Separators

TEST SEPARATORS

A vessel used to separate and meter relatively small quantities of oil and gas. Test separators can be two-phase, three-phase, horizontal, vertical or spherical. They can also be permanent or portable. Test separators are equipped with different meters to determine oil, water and gas rates, which are important in diagnosing well problems, evaluating production performance of individual wells, and managing reserves properly. Test separators are also often called well testers or well checkers.

PRODUCTION SEPARATORS

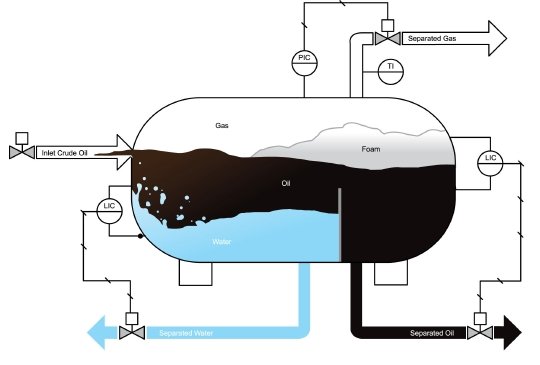

A separator is a pressure vessel used for separating different phases of a well stream. Vessel configuration may vary from horizontal to vertical and spherical depending on the application. Separation process is usually designed in stages in which the first stage separator is used for preliminary phase separation. Second and third stage separators are typically utilized for further treatments.

Separators can be used for gas/liquid separation (Two-Phase Separator) or oil/gas/water separation (Three Phase Separator). In the two-phase units, gas is separated from the liquid, passes through high-efficiency demisting equipment and is discharged from top outlet connections. The de-gassed liquid is routed to the bottom outlet in order to be transferred to downstream equipment.

Similarly, in three-phase separators the gas is separated from liquid while oil-water mixture is given a retention time. Retention time shall be sufficiently long in order to allow the water settle and drain while the oil spills over the weir (or similar arrangements) and is separated. Retention time is usually provided by operating experience or laboratory test data/ pilot plant operating test results.